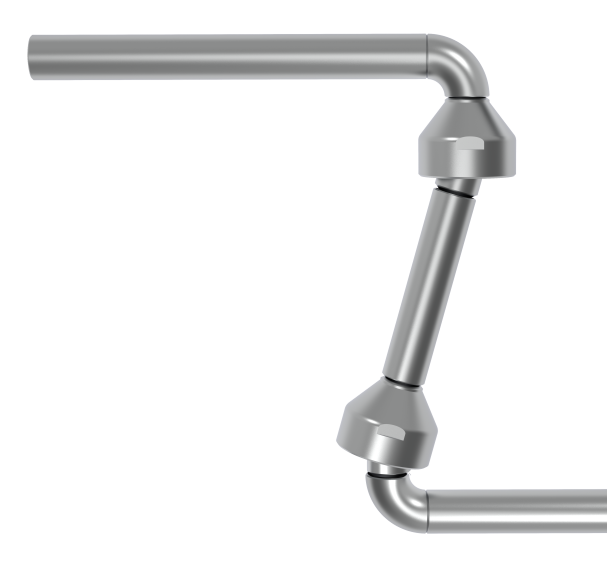

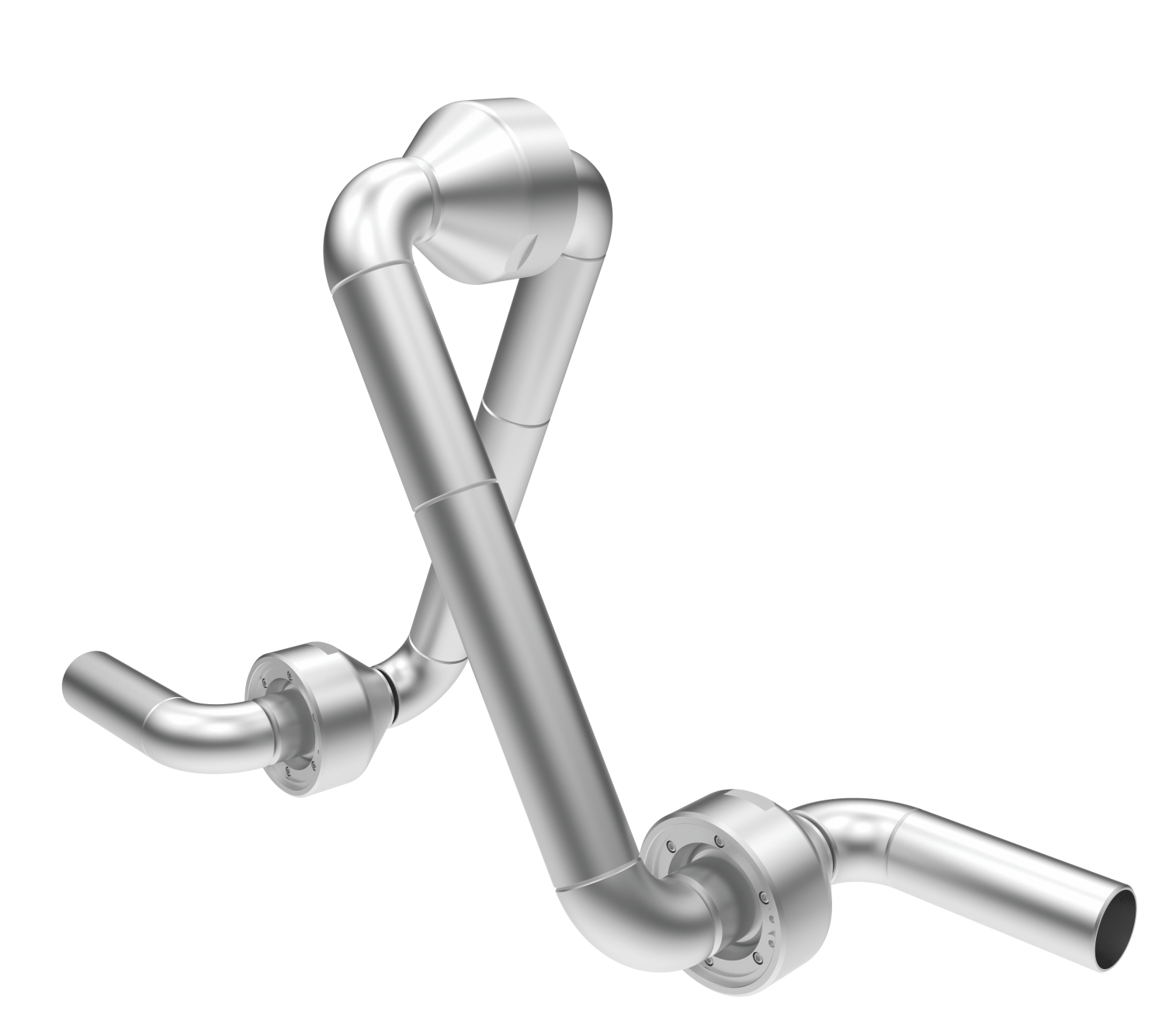

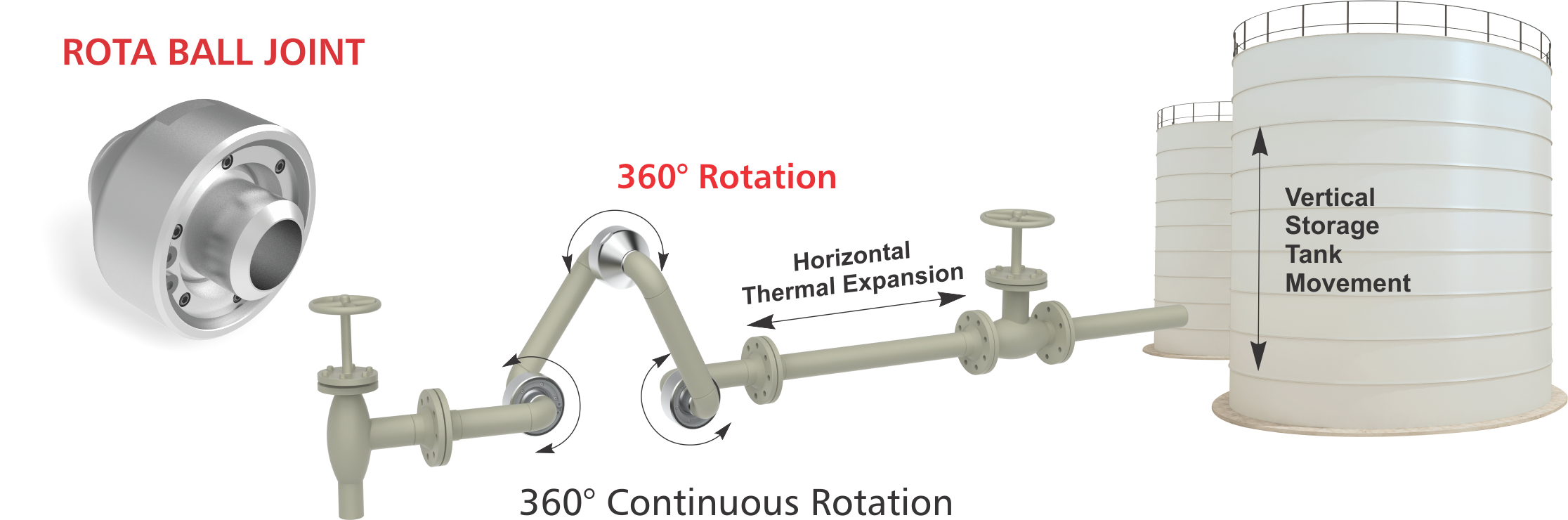

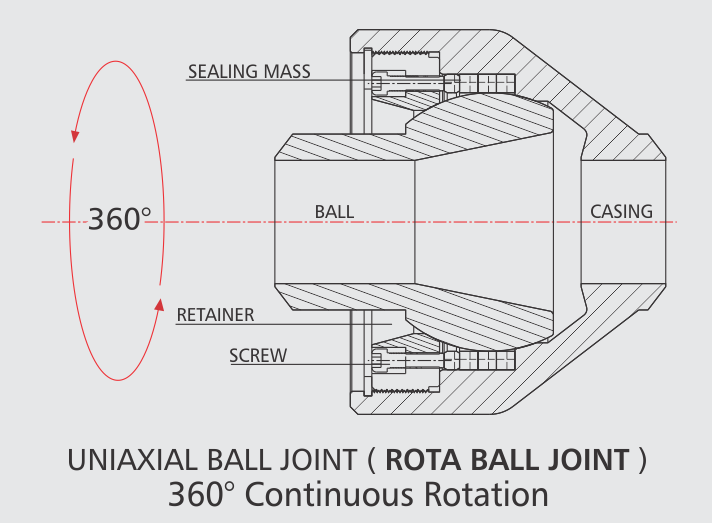

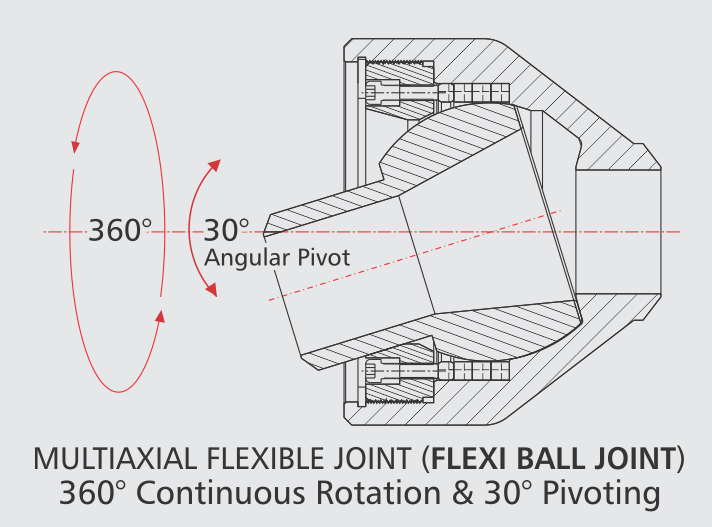

‘Fourwents’ Ball Joint Swivel Pipe Connector is engineered solutions for highpressure applications, allowing movement in piping systems and connected equipment without compromising the seal or increasing mechanical stress. It incorporates a durable seal built to endure extreme temperatures and pressures, and it can be conveniently maintained via an injection port located on the connector’s casing. This connector is well-suited for both static and dynamic applications, including steam systems, oil and gas, petrochemical plants, process industries, and marine operations. The ‘Fourwents’ Rota Ball Joint provides 360° continuous bidirectional rotation, while the Flexi Ball Joint offers the same full-range rotation along with an additional gimbal mechanism, enabling up to 30° of multidirectional pivot.

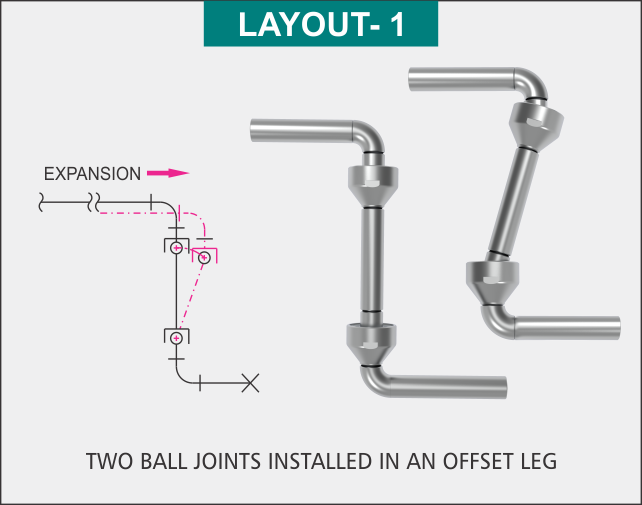

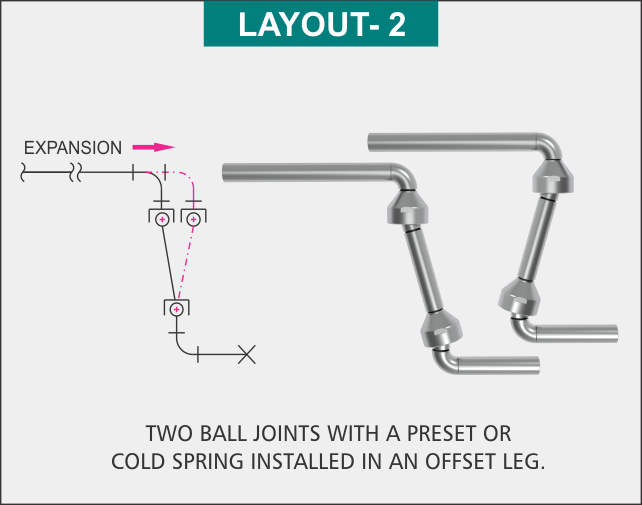

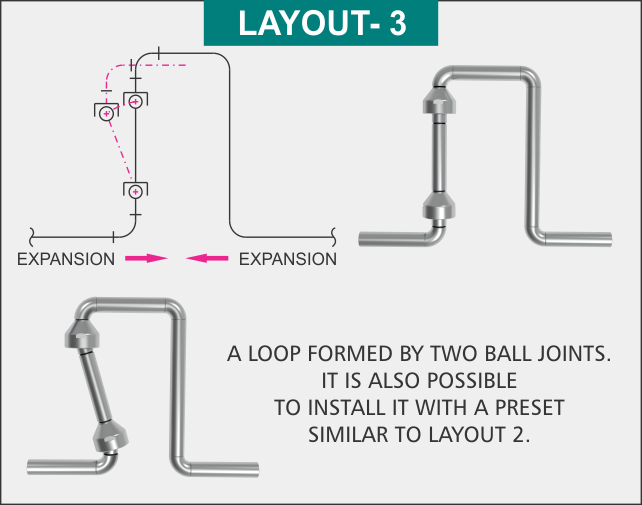

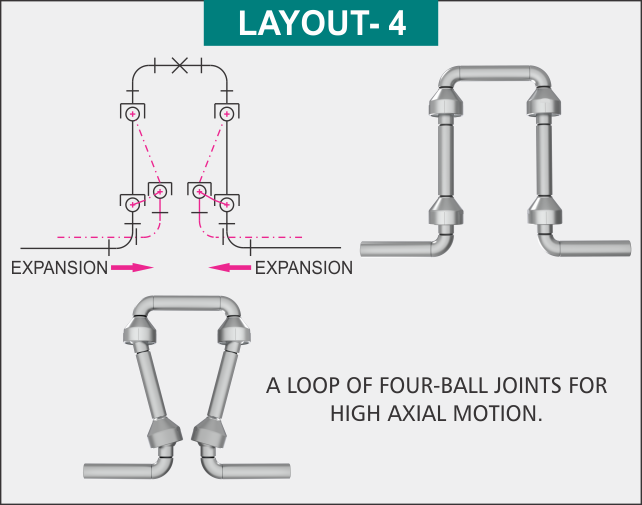

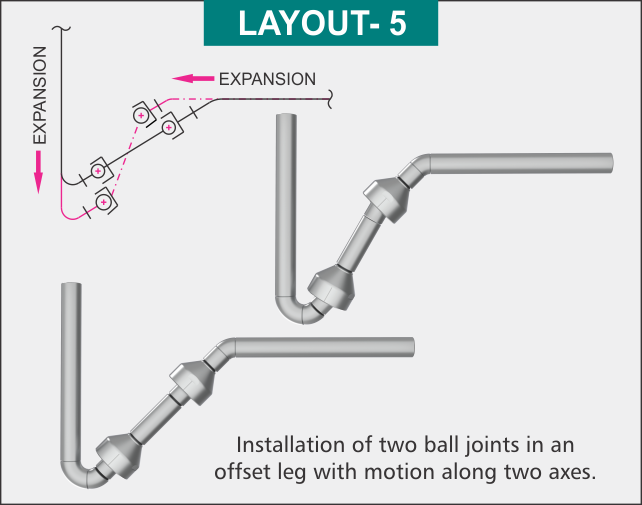

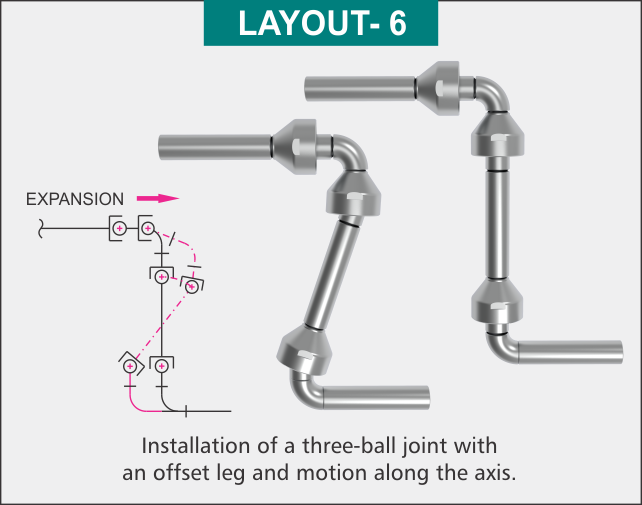

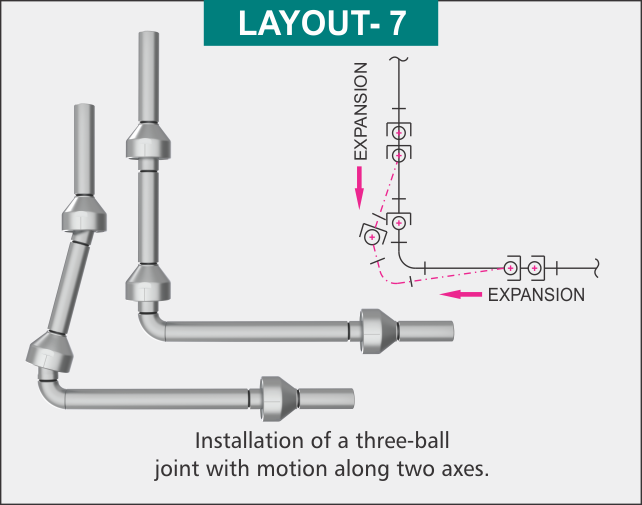

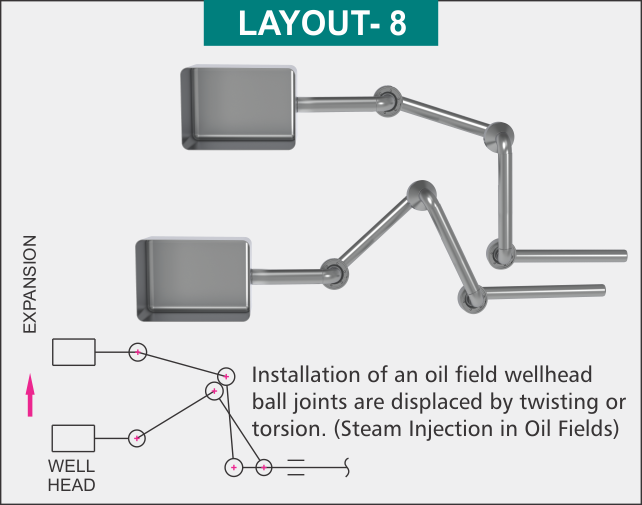

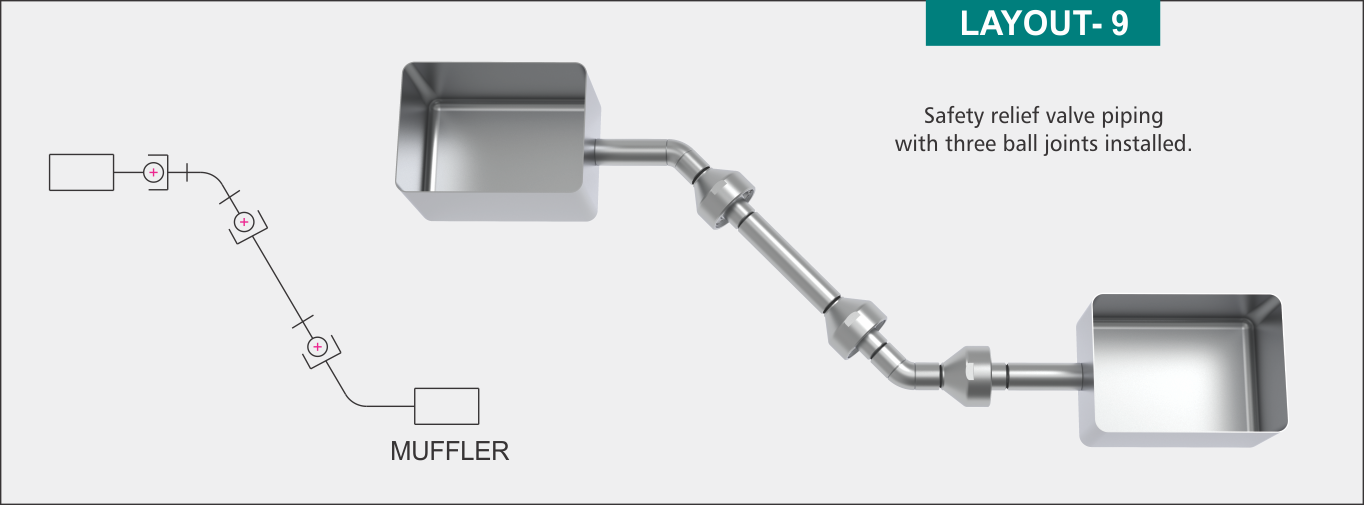

Ball joints can be used to absorb pipe movement in a variety of applications, including thermal expansion or contraction of pipe, tank, or building settlement, seismic movement, equipment movement such as solar panels and platens, and repetitive motion on bridges, oil platforms, and ships. The ability of ball joints to absorb motion is dependent on the OFF-SET Method, regardless of the source of the motion.

STANDARD DESIGN FEATURES

SPECIFICATIONS

SIZES:

1 in to 24 inch (Din 25 to Din 600)

PRESSURE RATINGS:

Up to ASME Class 2500

TEST PRESSURE:

1.5 x Design Pressure

TEMPERATURE RANGE:

Up to 1000°F (538°C)

MATERIALS:

END CONNECTIONS:

BALL JOINT DESIGN

BALL JOINT DESIGN

SPECIFICATIONS

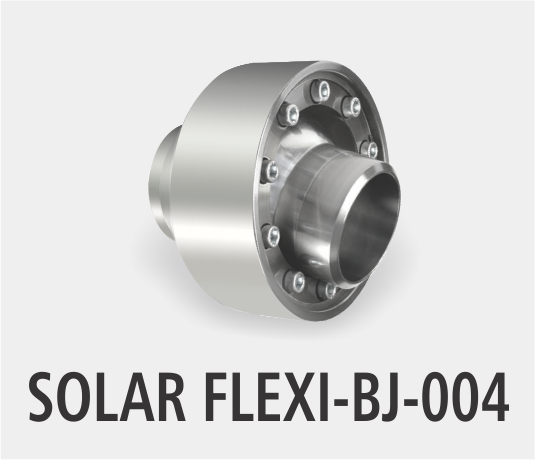

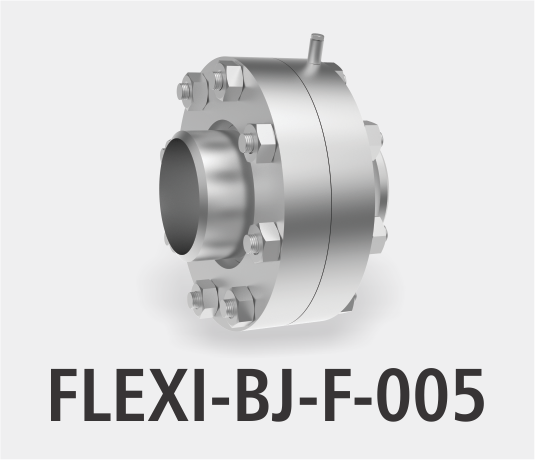

FOURWENTS BALL JOINT TYPES / MODELS

Available in 1” upto 24”(Inch) for ASME 2500# pressure class & temperature upto 1500°F, in a wide rang of material.

Available in 8” upto 24”(Inch) for ASME 300# pressure class & temperature upto 1500°F, in a wide rang of material.

Available in 1” upto 24”(Inch) for ASME 1500# pressure class & temperature upto 1500°F, in a wide rang of material.

Available in 2” upto 4”(Inch) for ASME 600# pressure class & temperature upto 1500°F, in a wide rang of material.

Available in 8” upto 24”(Inch) for ASME 1500# pressure class & temperature upto 1500°F.

| SIZES | PRESSURE RATING | END CONNECTION |

MATERIAL | |||

|---|---|---|---|---|---|---|

| ASME B16.5 | ISO 7005 | |||||

| CODE | CLASS | PSI | BAR* | |||

| 1.1/2″ DN 40 | 1 | 150 | 290 | 20 | BW = Buttweld |

|

| 2″ DN 50 | 2 | 300 | 750 | 50 | SW = Socketweld | |

| 2.1/2″ DN 65 | 3 | 400 | 1000 | 68 | FL1 = ANSI CL 150 | |

| 3″ DN 80 | 4 | 600 | 1500 | 100 | FL2 = ANSI CL 300 | |

| 4″ DN 100 | 5 | 900 | 2250 | 150 | FL3 = ANSI CL 400 | |

| 6″ DN 150 | 6 | 1500 | 3750 | 260 | FL4 = ANSI CL 600 | |

| 8″ DN 200 | 7 | 2500 | 6250 | 420 | FL5 = ANSI CL 900 | |

| 10″ DN 250 | FL6 = ANSI CL 1500 | |||||

| 12″ DN 300 | FL7 = ANSI CL 2500 | |||||

| 14″ DN 350 | FL8 = PN10 | |||||

| 16″ DN 400 | FL9 = PN16 | |||||

| 18″ DN 450 | FL10 = PN20 | |||||

| 20″ DN 500 | FL11 = PN50 | |||||

| 22″ DN 550 | FL12 = PN68 | |||||

| 24″ DN 600 | FL13 = PN110 | |||||

* Conforms to Pressure Nominale (PN) ISO 7005 |

FL14 = PN150 | |||||

| FL15 = PN260 | ||||||

| FL16 = Pn420 | ||||||

SPECIFIC (SPECIAL APPLICATIONS )

MANY OF OUR PRODUCTS ARE NOT SHOWN IN THIS CATALOGUE AS THEY ARE ONE -OFF ARTICLES ORDERED BY OUR CUSTOMERS.

THEY ARE EITHER MODIFIED VERSIONS OF OUR STANDARD ITEMS OR CUSTOM-BUILT ARTICLES WHICH ARE DESIGNED FRO SCRATCH IN ORDER TO FULFILL OUR CUSTOMER'S REQUIREMENTS IN TERMS OF AVAILABLE SPACE OR SPECIFIC OPERATING CONDITIONS.

EXAMPLES:

QUALITY & SERVICE

Factory engineered, manufactured and tested with in ISO 9001-2015 quality standard registered program. Fourwents Considerable experience and background, enables our customers to get the best and most reliable equipments for their application. Pre-assembled and shop tasted Ball Joints and Swivel Joints.