Onshore & offshore wellheads, tees and ells, manifolds, chokes, valve ends, compressors, general piping, loading risers, and pipelines.

Reactor vessel components include nozzles, closures, heads, tees, ells, manifolds, and valve ends. Piping & valves are used in petroleum rening and chemi cal processing facilities.

Subsea piping and riser systems, FPSO (Floating Production, Storage, and Offloading) vessels, and tanker loading and unloading facilities.

Steam lines, Pump inlet / outlet lines, General Piping / Valve ends and chemical clean out closures.

This section covers vessel closures, reactors, general piping, and valve ends.

Sanitary and general pipeline connectors, vessel closures, and valve ends..

Rocket test stands, fuel lines, hydraulic and pneumatic piping systems.

Hazardous waste disposal and fugitive emissions control.

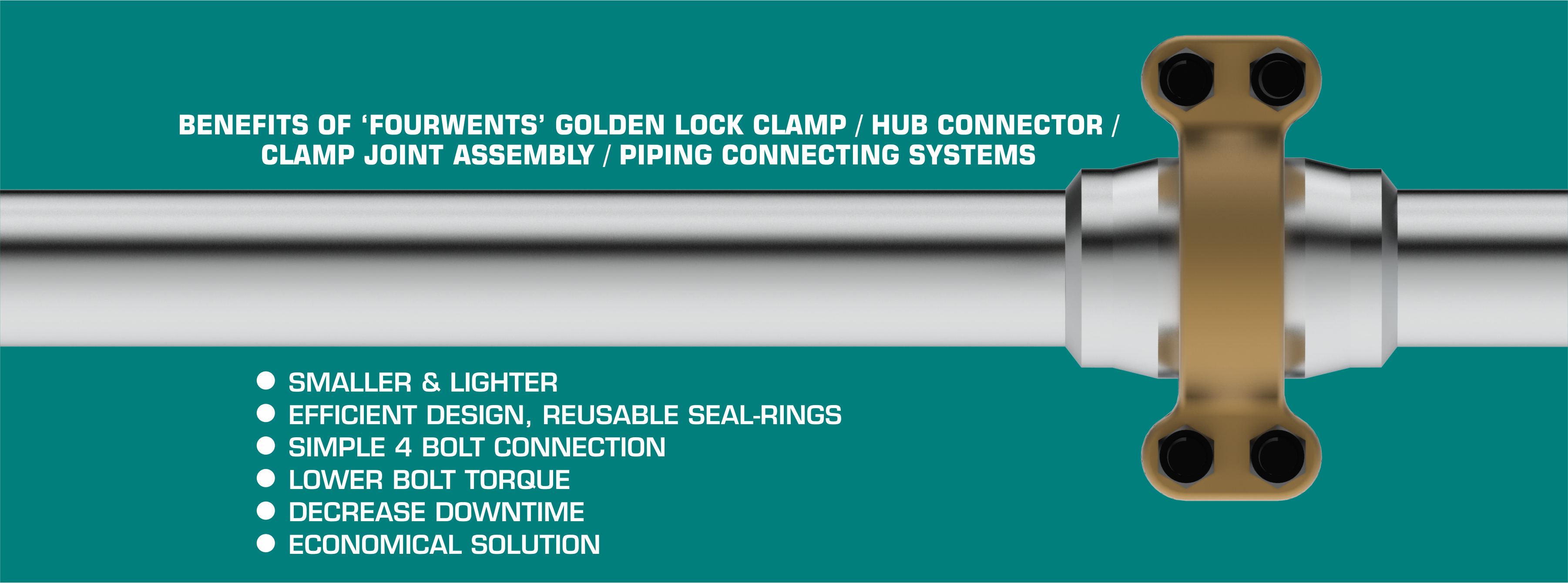

BENEFITS OF ‘FOURWENTS’ GOLDEN LOCK CLAMP / HUB CONNECTOR / CLAMP JOINT ASSEMBLY / PIPING CONNECTING SYSTEMS

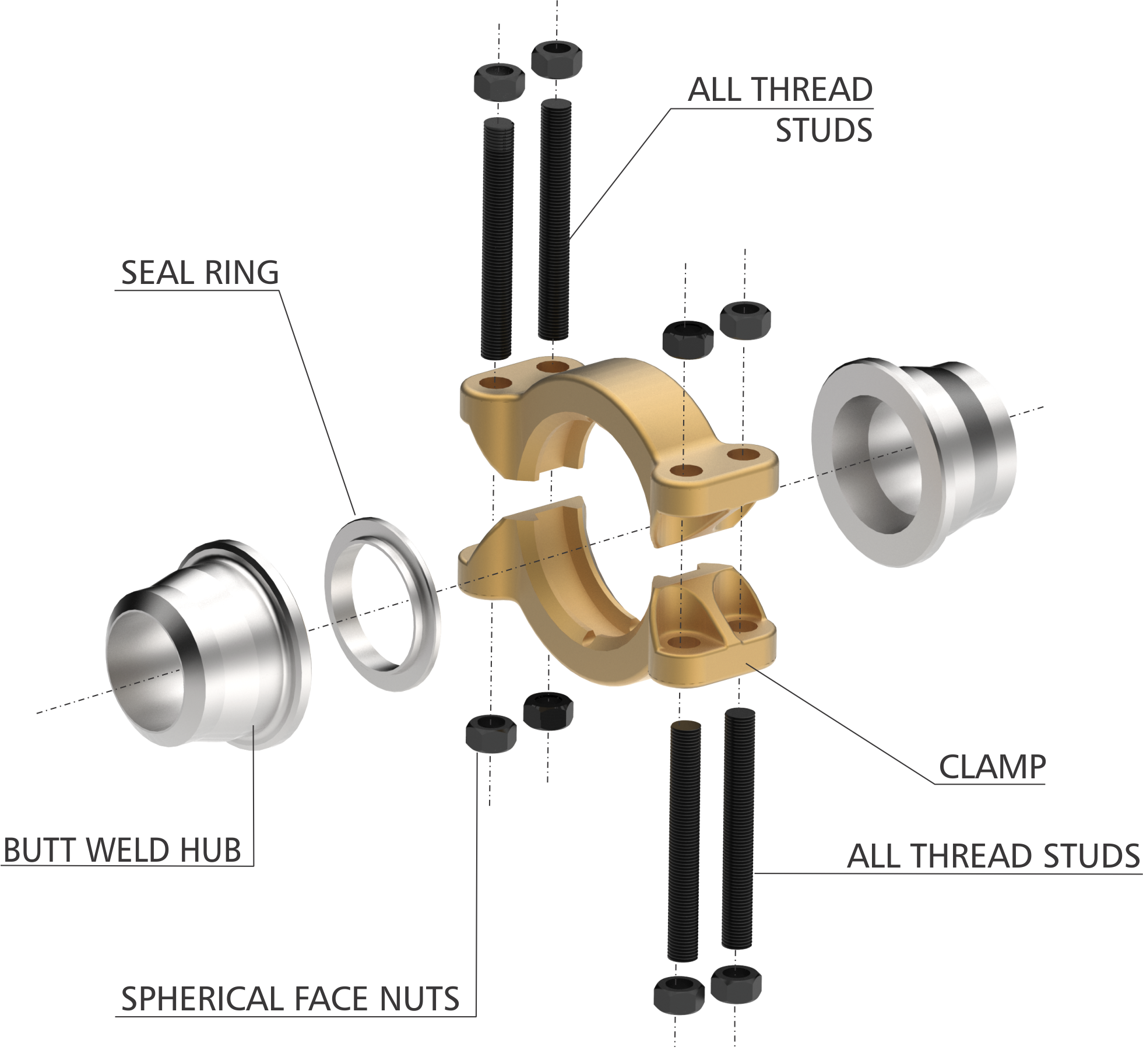

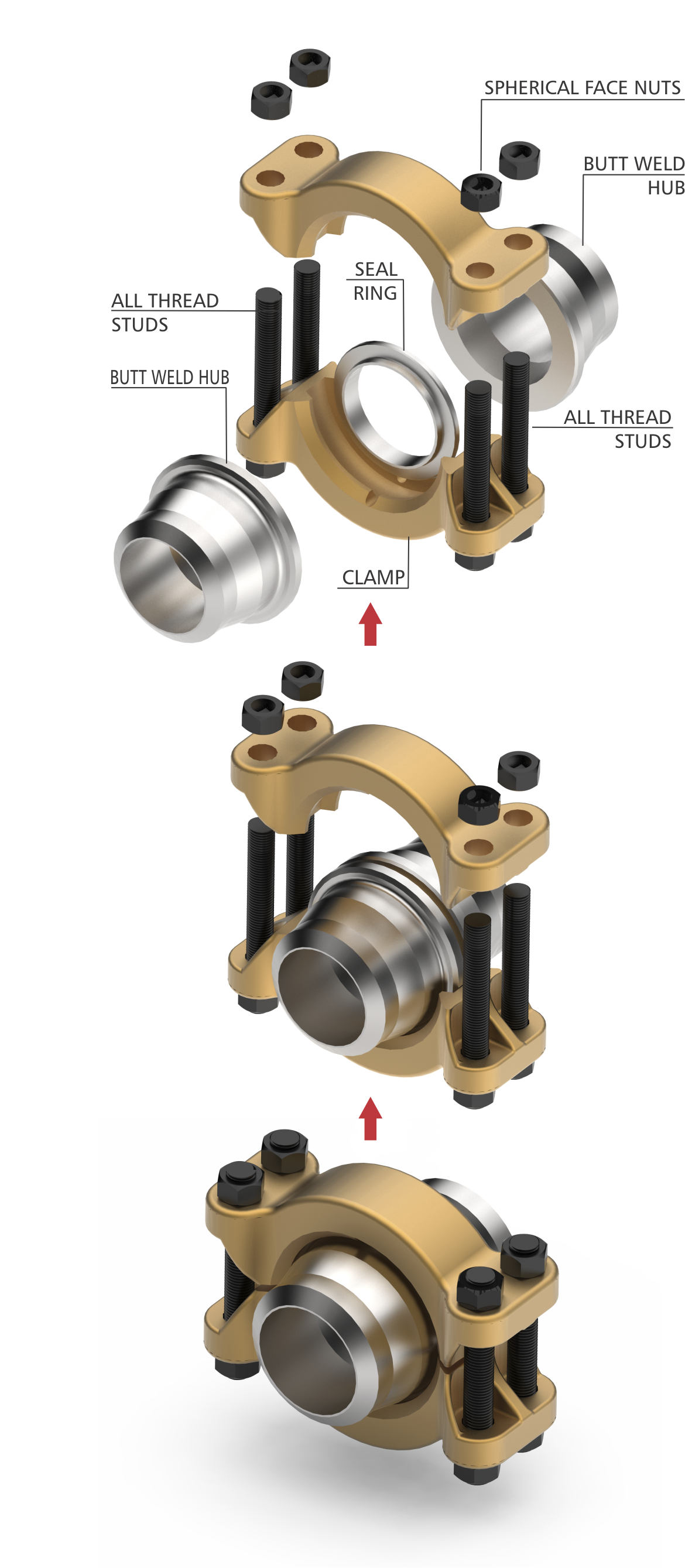

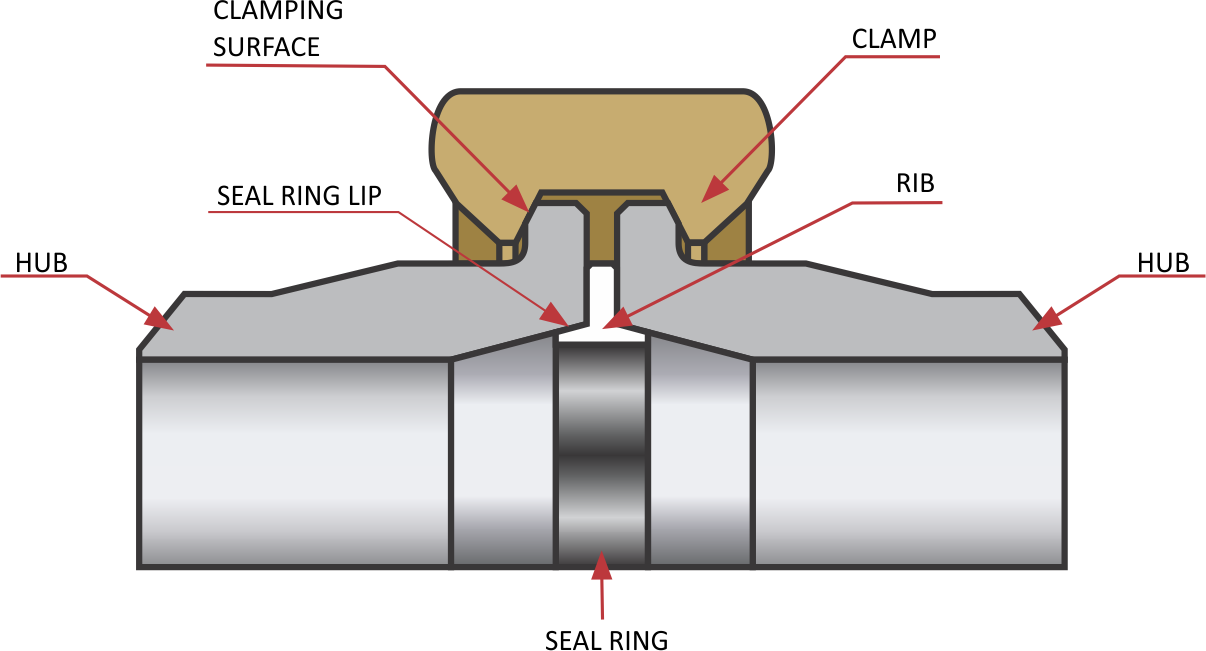

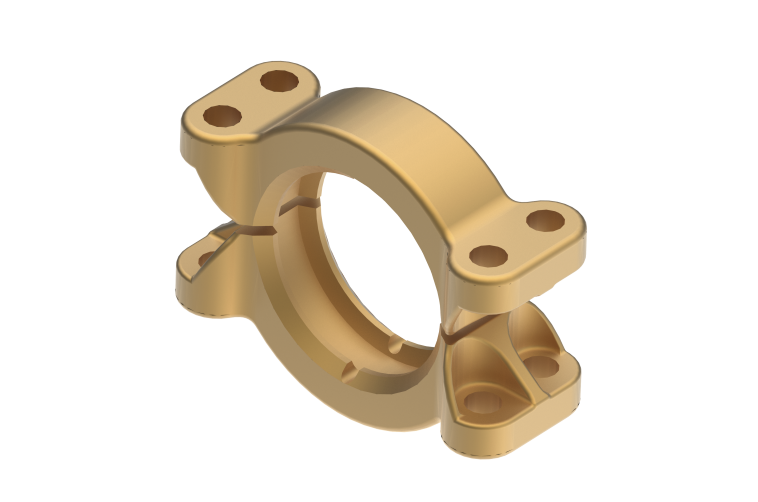

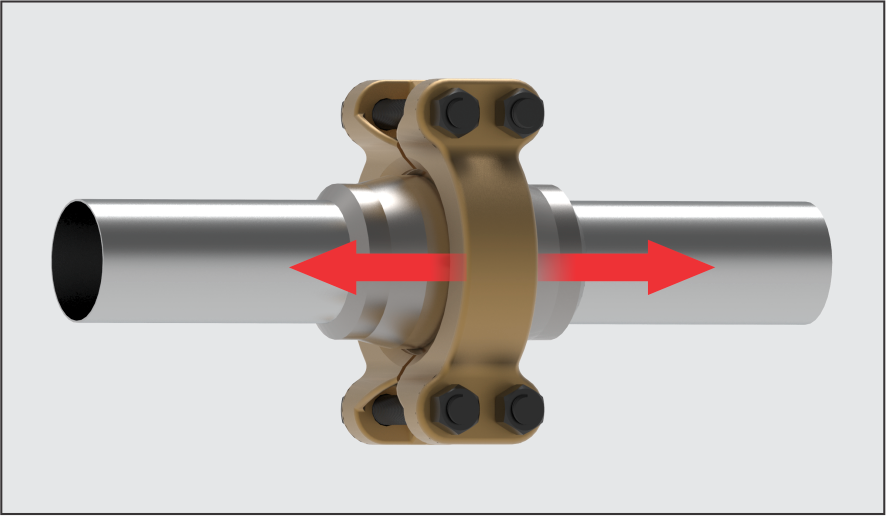

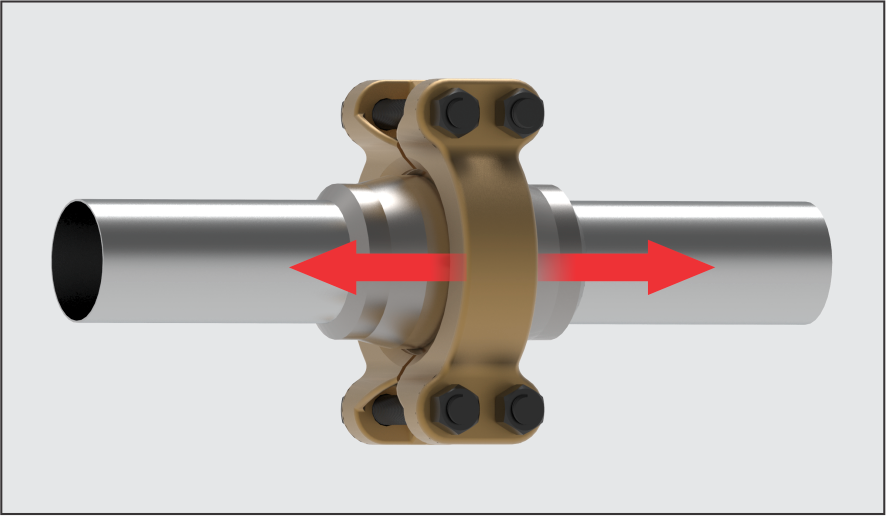

Fourwents GOLDEN LOCK is a fourbolt pipe clamp connection with two butt weld hubs welded to connecting pipes, two clamps (180º segments) spun around the hubs, and a sealing ring that its between the hubs.

The bolt set includes four studs and four spherically facing nuts that secure the clamps over the hubs and engage the assembly.

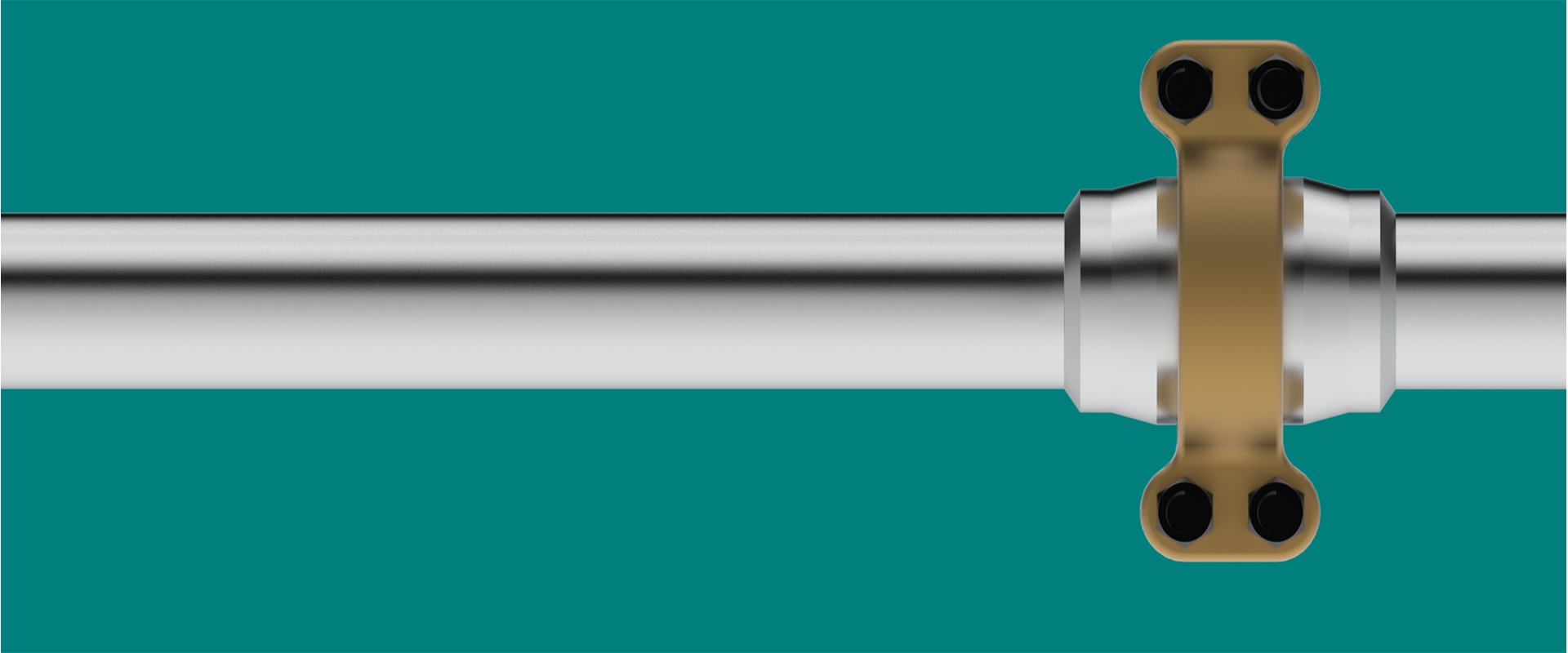

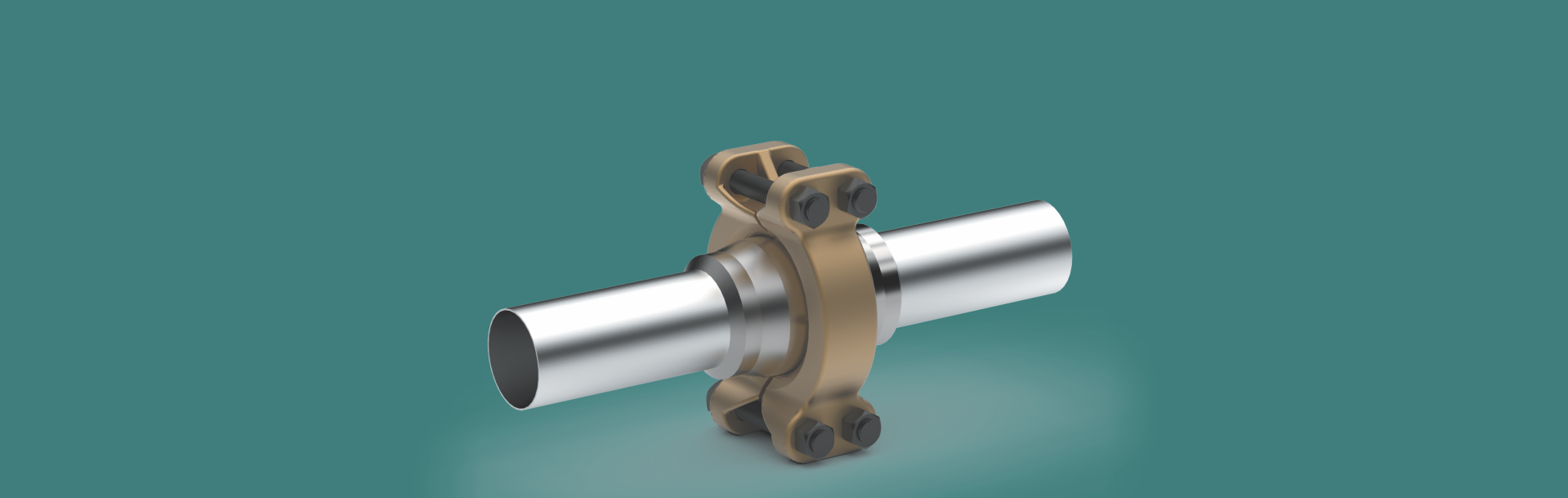

Fourwents ‘GOLDEN LOCK’ is a unique pipe clamp connector with quick connect and disconnect capabilities. It is suited for applications requiring space, weight, and joint integrity. GOLDEN LOCK outperforms ANSI and DIN ranges due to its greater characteristics.

The ‘GOLDEN LOCK’ pipe clamp connections are interchangeable with any other type connectors.

Fourwents ‘GOLDEN LOCK’ is compliant with ASME Section III, Class 1, 2, 3, 6, CSA Can 3 N285.0, and ASME Section VIII division 1 & 2.

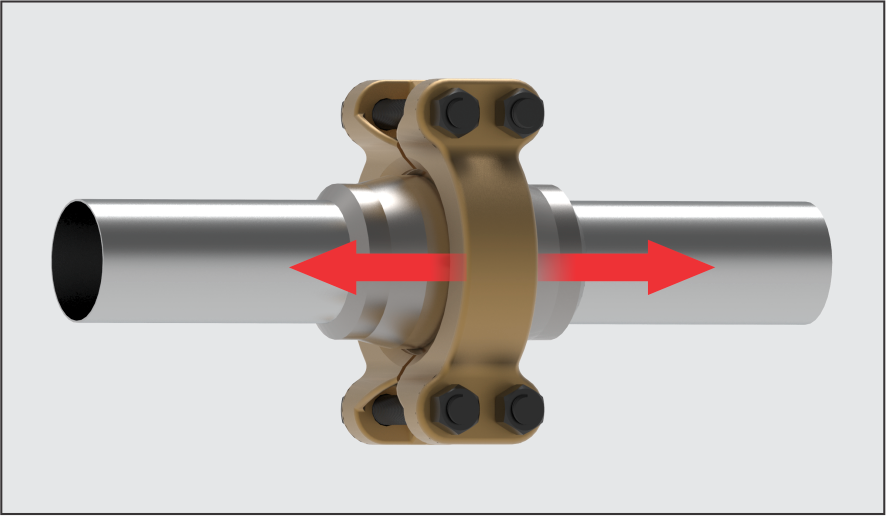

The ‘Golden Lock’ connector offers the chance to build lightweight, compact systems since it is substantially lighter and smaller than an equivalently rated ANSI or API ring joint ange connector. The clamp fully rotates around the hub, making it simple for position the pipes and hookups. SHORTER LENGTH, SMALLER DIAMETER, NO BOLT HOLES TO LINE UP.

The rib of the seal ring is clamped between the hub faces. The lips of the seal ring engage the inner hub surface in an interference t, Which deects the lips to form a seal.

The clamp secures the two hubs against the seal ring ribs. The clamp assembly draws the hubs together, causing the seal ring lips to deect against the hubs' inner sealing surfaces. This deection elastically loads the lip of the seal ring against the hub's inner sealing surface, resulting in a self-energized seal.

A seal ring's cross section is shaped like a "T". As the connection is created, the legs of the "T" form a rib that is supported by the hub faces. Two arms form a lip seal on the hub's inner surface, which serves as the sealing surface. Internal pressure helps to reinforce the seal.

Designed for almost 360° clamping

contact with the hubs. A relief notch

in the clamp segments allows for

uniform distribution of makeup

forces.

There is no need for a certain

orientation when installation.

The Forwents 'Golden Lock' connector operates better when constructed of the same material as the pipe and a majority of other components that may be connected.

The rib of the seal ring keeps the seal lip from being crushed by over-tightening. The rib serves as a positive stop during makeup, but it also distributes compressive and bending loads from one hub member to another. The rib bearing area is large enough to support the most severe loading that a piping system can sustain.

‘FOURWENTS’ ‘GOLDEN LOCK’ CONNECTORS CAN EXPERIENCE VIBRATION, HEAT, COLD, AND THERMAL SHOCK DURING HEAVYDUTY USE. GOLDEN LOCK CONNECTORS REGULARLY WITHSTAND HARSH CONDITIONS WITHOUT REQUIRING ROUTINE MAINTENANCE. SPECIAL DESIGNS ENABLE MAINTENANCE-FREE SERVICE EVEN IN THE HARSH CONDITIONS SHOWN IN THE TABLE.